MYCY14-1B Axial Piston Pump

With simple structure, small volume, high efficiency, light weight, low noise, long life, strong self-priming ability and other advantages, it is suitable for forging machinery, machine tools, ships, aviation, metallurgical machinery, plastic machinery, engineering machinery and mining machinery and other hydraulic equipment

Product Introduction

Product Overview:

CY14-1B series pump is an axial piston pump with cylinder rotation and variable head (swash plate) variable. Due to sliding boots and variable between head, oil distribution plate and the cylinder body adopts hydraulic static equilibrium design of oil film thickness between the two surface of sport in the pure liquid friction under operation, and eliminating the heavy thrust bearing, and compared with other types of pump, has a simple structure, small volume, high efficiency, light weight, low noise, long service life, strong self-priming capacity, etc, It is suitable for hydraulic equipment such as forging machinery, machine tool, ship, aviation, metallurgical machinery, plastic machinery, engineering machinery and mining machinery.

Working Principle:

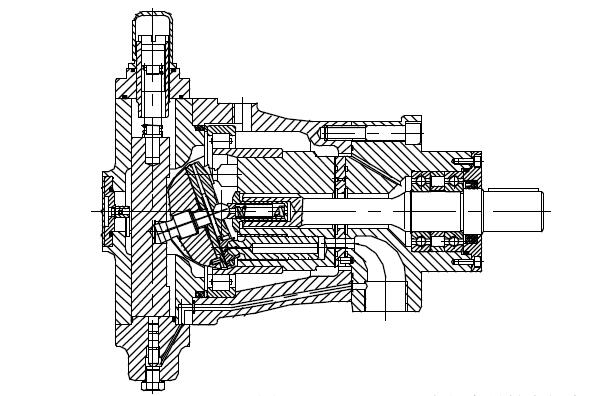

The main part (see structure section) by the drive shaft drive cylinder rotation, so that the seven plungers evenly distributed on the cylinder revolve around the center line of the drive shaft, through the central spring will slide the slipper in the column slide assembly pressure on the variable head (or swash plate). In this way, the plunger reciprocates with the rotation of the cylinder block to complete the action of oil absorption and oil pressure. This pump is dependent on internal control (or external control) oil pressure control variable mechanism. The pressure adjustment range of the pump is relatively small, the oil pressure in 3~ 4MPa when the variable, the flow rapidly reduced to the required high pressure flow value. This kind of pump is equivalent to the combination of high and low pressure pump in fact. The driving power selection of the pump can be calculated by referring to the power selection method of the pressure compensation variable pump. The high pressure oil from the main part enters the lower chamber of the lower flange (D), when the spring force is greater than the liquid pressure acting on the lower end area of the push rod, the variable piston is pushed to move down, so that the flow of the pump increases. When the liquid pressure on the lower end area of the push rod is greater than the force of the spring, the variable piston moves up, reducing the flow of the pump.

Adjusting variable characteristics, according to the required flow and pressure variation range, adjust the adjustment sleeve, so that the flow of the pump final pressure does not change, and then adjust the adjustment screw so that the pump flow just changed when the initial pressure meets the requirements.

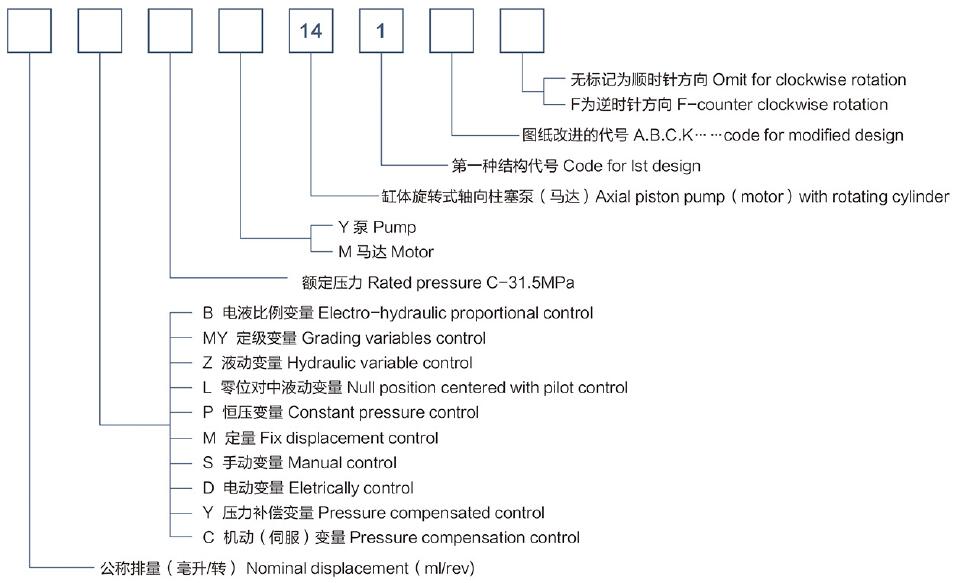

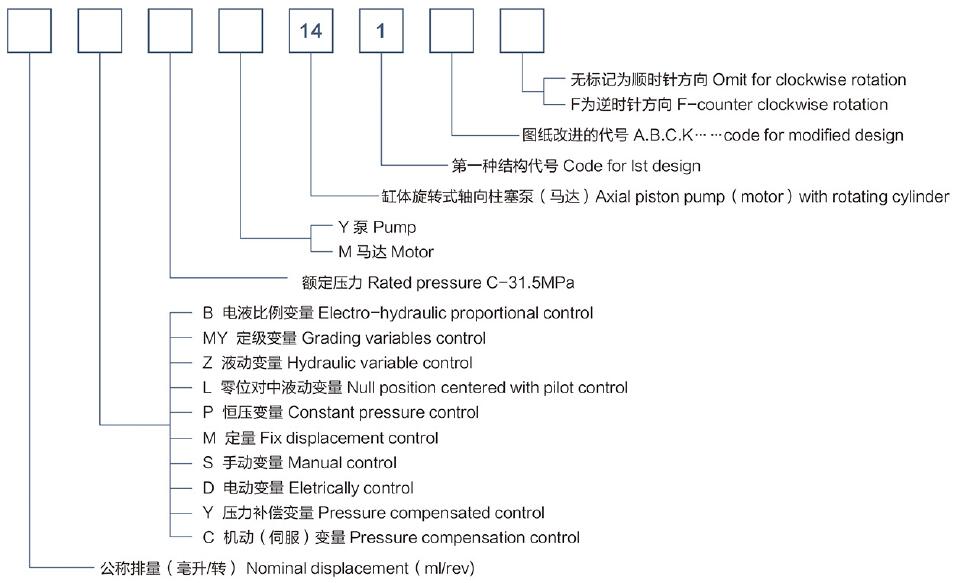

Model Specification:

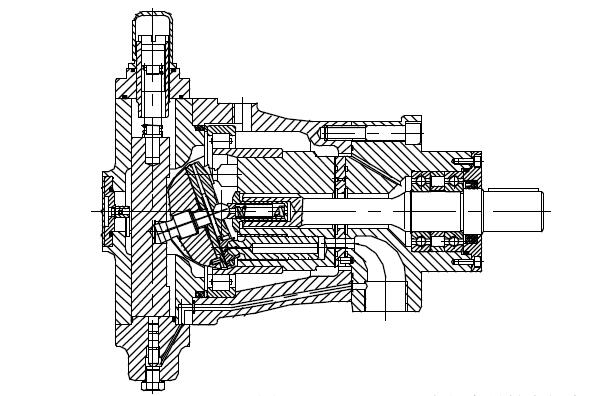

Structure Chart:

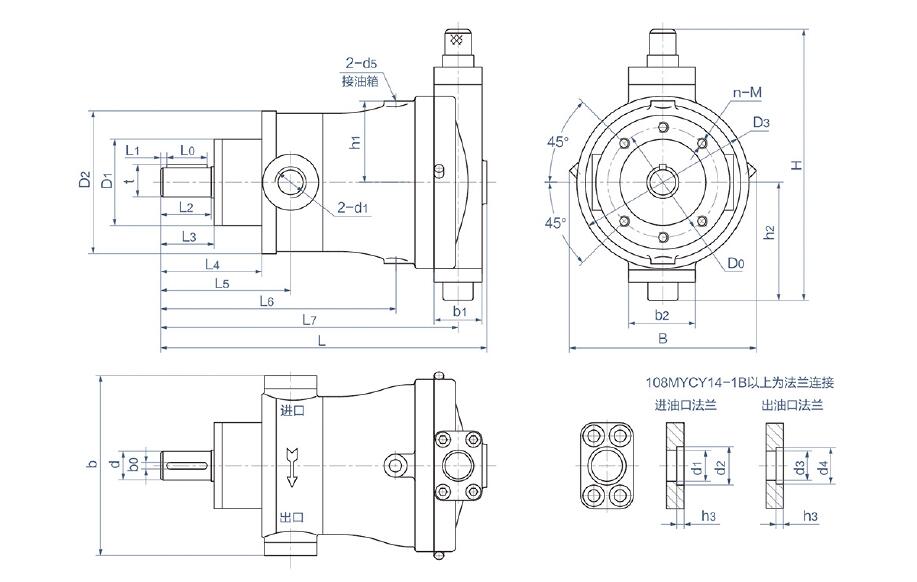

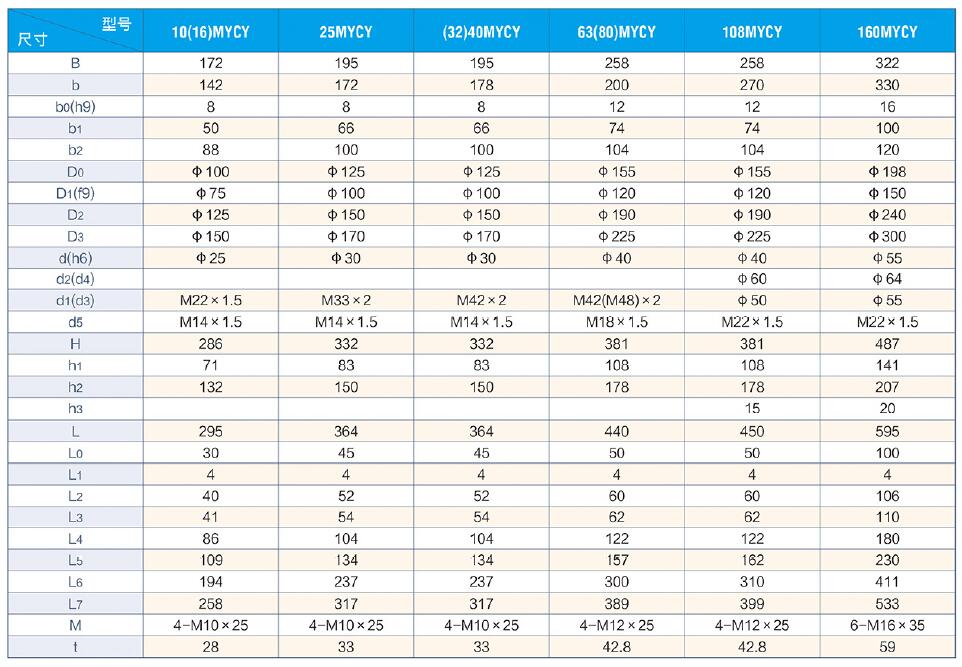

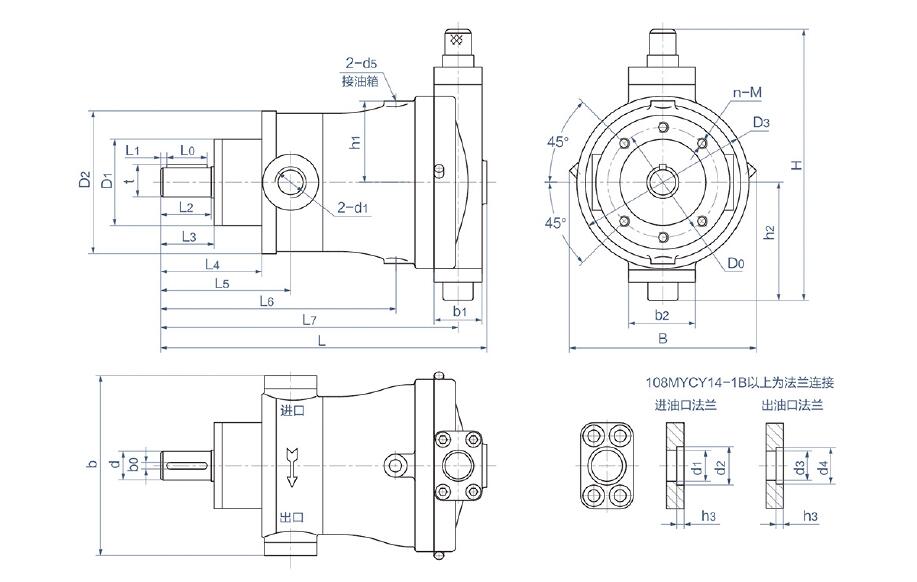

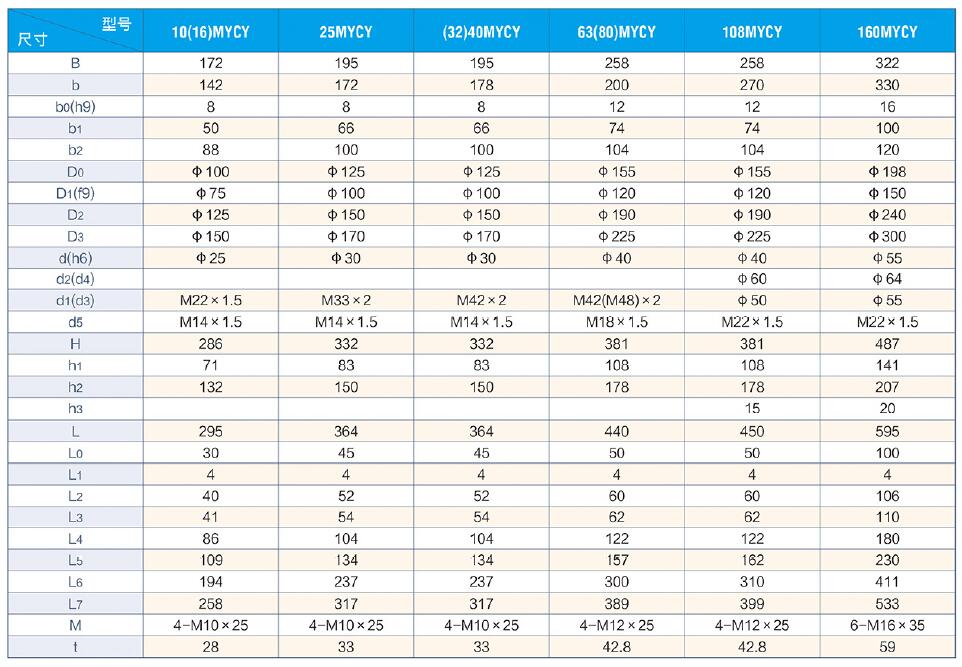

Overall Dimensions:

Model Specification:

Structure Chart:

Overall Dimensions: